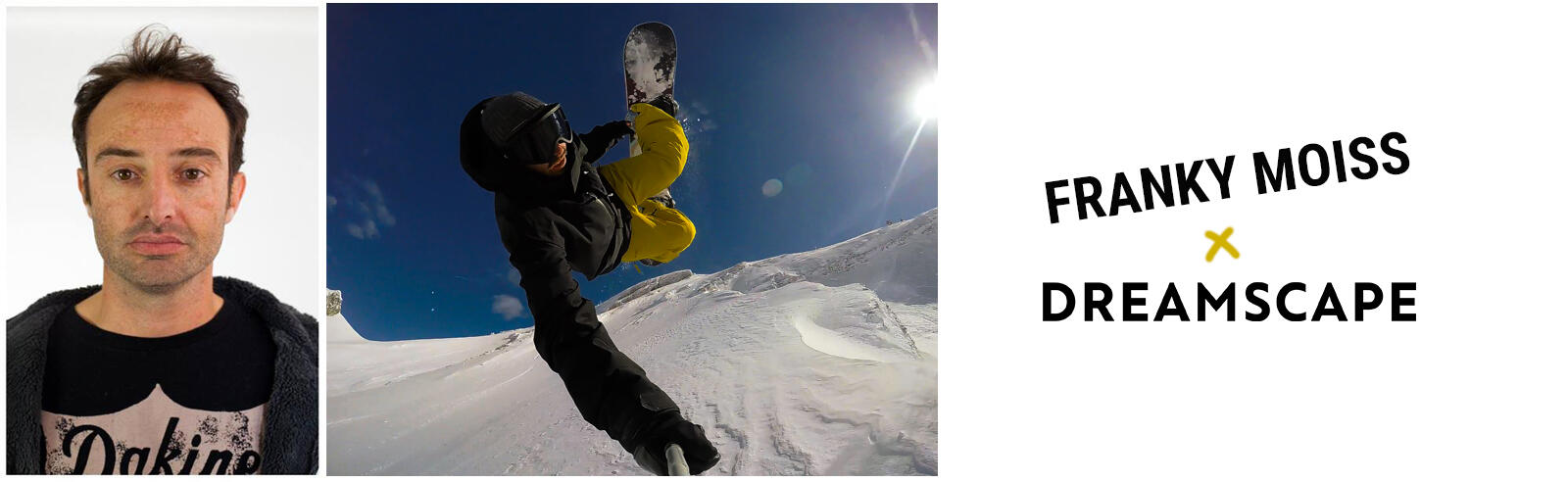

Meeting with franky moiss, former professional rider

(Yohann, product manager at Dreamscape) Hello Franky, today we are here to speak of our work. Before beginning, can I introduce you, for those who don't know you?

I am called Frank Moissonnier. I am often known as Franky Moiss. Moiss because Moissonnier is far to long on the international scene and I had to shorten it a bit so that people could pronounce my surname. I do understand, in English it doesn't work great. (laughs)

I was a professional snowboarder for about fifteen years. I say professional as I did some competitions, but it was more the brand image side that made my career, rather than competition. Although I competed in quite a few, like Air & Style, the team challenge, the Empire check down, all those mythical snowboarding events.

Can you tell us your first snowboarding memory? How old were you?

My first snowboarding memory, I think I had rented a Look. It must have been in 92. I was 15.

With ski boots... and plates. I remember being on my butt quite a bit. It was in La Clusaz, on quite a flat slope... to learn. We were on our butts quite a bit, but since we were skateboarders, I soon got the hand of it I think I managed to do Ollies on the first day "yippee"! It wasn't very stylish, but it must have been cool at the time Then the next season, I bought a board with bindings from a friend. It was a Burton Air 600. No! It was before the Burton Air, it was a Burton Free Six. It was my first real snowboard.

For the people watching us, how long have you worked with Dreamscape?

It has been 3 years now. These past two seasons, we designed products and filmed together. The first year, I already did a few tests and gave product feedback.